Xinhua News Agency, Shanghai, May 28. Question: Please see the data flow from the front line of production – directly on the resumption of work and production in Shanghai

Xinhua News Agency reporter

In May, the sycamore branches along the streets of Shanghai are lush and leafy. The factory parks that have resumed work and production in full swing are busy and orderly, and they are gradually returning to their former vitality.

Tens of thousands of tons of photoresist “charter flights” have arrived in Shanghai one after another, and the production capacity of important Shanghai chip manufacturing enterprises has reached more than 90% of normal production capacity; the single-day container throughput of Shanghai Port, an international shipping hub, has exceeded 110,000 TEUs, returning to 90% before the outbreak. %; SAIC Motor’s overseas sales in May are expected to be 1.6 times that of the same period last year, and Tesla’s Shanghai Gigafactory delivered more than 180,000 vehicles in the first four months, more than 1.7 times the delivery volume in the same period last year; Shanghai Siemens Medical Equipment has achieved 100 % Full-load production to meet domestic and foreign market demand…

The epidemic must be prevented, the economy must be stabilized, and development must be safe. At present, in Shanghai, coordinating epidemic prevention and control and economic development, more and more workshops are roaring, converging into a powerful pulse of the industrial chain and supply chain.

At 6:52 on May 14, the C919 aircraft numbered B-001J took off from the 4th runway of Shanghai Pudong Airport and landed safely at 9:54, marking that COMAC will deliver the first C919 to its first customer. The first flight test of the large aircraft was successfully completed.Xinhua News Agency

The heavy weapon of a great power, highlighting the strength of the hard core

On the coast of the East China Sea, the C919 large aircraft successfully completed the first flight test of the first aircraft to be delivered to the first user, a step closer to the official delivery.

In Pudong New Area, employees of Hua Hong Group’s Jinqiao, Zhangjiang and Kangqiao factories are closed to ensure stable production capacity and “core” fire. According to the financial report released by Hua Hong Semiconductor in the first quarter, its sales revenue reached a record high of US$594.6 million, a year-on-year increase of 95.1%.

An interior scene of Hua Hong Group taken on May 19.Xinhua News Agency

On the bank of Changxing Island, the 99,000-cubic-meter super-large ethane carrier built by Jiangnan Shipbuilding, a subsidiary of China State Shipbuilding Corporation, was delivered on schedule. In the first five months of this year, the amount of orders received by Jiangnan Shipbuilding increased by 76% year-on-year in 2021, witnessing the confidence of the global shipping market in China’s shipbuilding industry.

In order to win the “Great Shanghai Defense War”, all walks of life in Shanghai make concerted efforts, and every second counts. Step up production in the park factory area where closed and controlled operations and centralized offices are located; at the forefront of scientific research and industry, technological innovation has overcome difficulties; it has made every effort to ensure major projects.

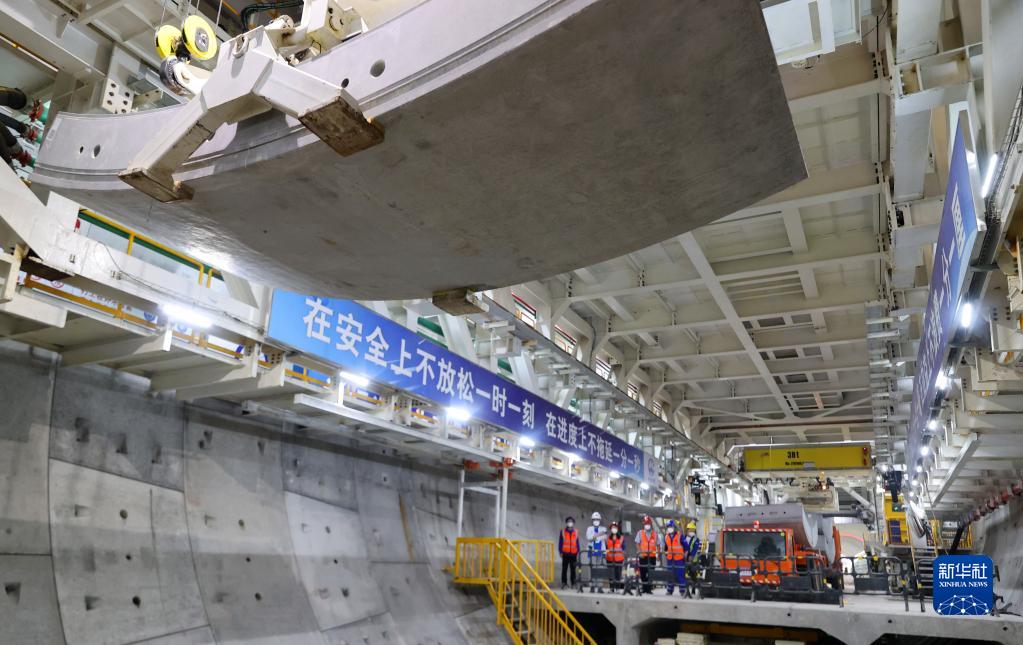

On May 28, in the 11th bid section of the Shanghai Rail Transit City Line Airport Contact Line Project, workers were carrying out electric welding operations.Photo by Xinhua News Agency reporter Fang Zhe

Recently, Lingang New Area, Fengxian District, Jiading District, etc. have promoted the settlement of industrial projects by means of “cloud signing” and “cloud docking”, and integrated circuits, biomedicine, artificial intelligence, and new energy vehicles have become the protagonists.

“At present, the declaration of the third batch of ‘white list’ for resumption of work and production in the integrated circuit industry has been completed, involving more than 100 enterprises. With the improvement of the epidemic prevention and control situation, more and more enterprises have gradually resumed operation.” Shanghai integrated circuit industry Guo Yiwu, secretary general of the association, said.

When the loading and unloading production of ocean-going freighters is running efficiently, the trucks carrying car chips are smooth, and the production lines of batches of enterprises that have resumed work and production are flowing, the vitality of the city’s development is coming back.

On May 28, in the 11th bid section of the Shanghai Rail Transit Municipal Line Airport Contact Line Project, workers operate segment cranes for construction work.Photo by Xinhua News Agency reporter Fang Zhe

Industry leader, leading the industry “chain”

Leading enterprises, lead the whole “chain”. Leading enterprises in the automobile, steel, intelligent manufacturing and other industries have resumed operation, and can play the role of connecting the chain with the point and the surface with the chain. However, large-scale enterprises are densely staffed, have long supply chains, and have a wide range of impacts. It is not easy to ensure a steady resumption of work and production on the premise of firmly adhering to the “safety line” of epidemic prevention and control.

Under repeated stress tests and process optimization, a number of key enterprises such as SAIC, Baosteel, Shanghai Xinshida Electric, and Shanghai Zhenhua Heavy Industry have steadily and steadily pushed forward the resumption of work and production.

Baosteel Co., Ltd., a subsidiary of China Baowu, maintains the “two correctness” of epidemic prevention and control and production and operation. In the first half of April, Baosteel Co., Ltd. successfully completed the normal production plan of iron and steel, and the effective operation rate of important operation lines in Baoshan Base reached 94.69%.

As a leader in domestic energy equipment, as the epidemic prevention and control situation in Shanghai continues to stabilize and improve, Shanghai Electric has pressed the “fast-forward button” to resume work and production in various industrial sectors and key enterprises. As of May 23, the actual number of employees of the group reached 13,617, and the planned arrival rate has reached 80%.

“The Shanghai Xinshida Robot Super Factory has kept production since the outbreak of the epidemic,” said Wu Yuhui, director and general manager of Shanghai Xinshida Electric Co., Ltd. “As of May 27, including the robot super factory, The production capacity of Xinshida’s four factories in Shanghai has returned to 75% to 85% of normal production capacity.”

The gradually resumed production operations are constantly meeting market demands.

On May 25, a batch of SAIC Group passenger cars were parked at Shanghai Haitong International Automobile Terminal for shipment (drone photo).Photo by Xinhua News Agency reporter Fang Zhe

In the early morning of May 25, more than 1,000 new vehicles of SAIC Group’s own brand MG and Datong brand were lined up on the Haitong Wharf in Waigaoqiao, Shanghai, slowly lined up on a ro-ro ship and shipped to Australia. Under the epidemic, China’s auto exports have never stopped, and overseas sales have continued to grow.

“Chinese cars are very popular overseas. Even with the impact of the epidemic, the throughput of our terminal from January to April increased by 32% year-on-year.” said Xi Jialin, executive director of the marketing department of Shanghai Haitong International Automobile Terminal Co., Ltd.

According to information from SAIC, since May, Haitong Terminal alone has exported tens of thousands of SAIC’s own brand vehicles. It is expected that overseas sales in May will exceed 70,000, a year-on-year increase of more than 60%.

By opening up the “chain”, leading enterprises have played a leading role in the industry. Raw materials can come in, production can be stable, and products can go out. The large gear of the industry leader drives many small gears in the industrial chain to work together. “At present, the coordinated production of some products in factories in Shanghai, Hangzhou, Shenzhen and other factories and the coordinated supply of raw materials at two points and one line have been realized.” Wu Yuhui said.

On May 14, workers work in the factory of Shanghai Tofflon Pharmaceutical Equipment Manufacturing Co., Ltd. in Jinshan District, Shanghai.Xinhua News Agency

Internal and external and “stable”, it is expected to add confidence to the good

Stable production and stable chain means stabilizing expectations and boosting confidence.

“We have achieved 100% full-capacity production, which can meet the needs of domestic and foreign markets and ensure the orderly operation of the global supply chain.” said Kong Jun, senior vice president and general manager of Shanghai Siemens Medical Devices Co., Ltd., “China’s economic advantages will not Changed because of the epidemic, we are still full of confidence in the Chinese market and in Shanghai.”

The loading site of Tesla electric vehicles at the Nangang Wharf in Shanghai on May 11. This is the first batch of whole ship exports after the resumption of work and production at Tesla’s Shanghai Gigafactory.Xinhua News Agency

As Tesla’s “global export center”, Tesla’s Shanghai Gigafactory has delivered more than 180,000 vehicles in the first four months of this year, more than 1.7 times the delivery volume in the same period last year, and has surpassed the factory’s full-year delivery volume in 2020 .

Tao Lin, Tesla’s global vice president, said: “We believe that the epidemic is just a test and challenge. We have seen the ability of all walks of life to cope with the challenges during the resumption of work. We believe that production will soon return to normal.”

As the world‘s leading specialty chemicals company, two Huntsman Group companies in Shanghai were included in the first batch of “white lists” for resumption of work and production. Pan Lumin, president of Huntsman Polyurethanes Division Asia Pacific, said: “The challenges brought about by the epidemic are temporary. Huntsman will continue to firmly root in China and serve China.”

The impact of the epidemic on the development of the industry is in the whole chain, so the solid progress of resumption of work and production also needs to be broken down by each problem in the whole chain.

“The elevator industry cannot operate without one component,” said Chen Jian, general manager of the German company Tisheng Elevator (Shanghai) Co., Ltd. “In addition to the return of employees in key positions, the government departments actively communicated and coordinated multiple inter-provincial transportation passes. , opened up transportation congestion, and helped us solve our urgent needs.” Since late May, the company has resumed work and production at a faster pace, trying to make up for the previously delayed time and production.

Wu Jincheng, director of the Shanghai Municipal Commission of Economy and Information Technology, said that in order to promote the resumption of industrial production and production in an orderly manner, in the next stage, Shanghai will also release active policies to help enterprises, effectively benefit the main body of enterprises, and speed up the recovery of the resilience and competitiveness of the industrial chain and supply chain. .

The 99,000-cubic-meter B-type cabin super-large ethane carrier H2625 built by Jiangnan Shipbuilding, a subsidiary of China Shipbuilding Corporation, was photographed on May 16 (drone photo).Photo by Xinhua News Agency reporter Ding Ting

Logistics operation to ensure the smooth flow of “aorta” and “microcirculation”

The smooth flow of goods is an important guarantee for the resumption of work and production. Since the outbreak of the current round of the epidemic, sea, land, rail, and air have given full play to their comprehensive transportation advantages, and tried their best to break through congestion and make up for breakpoints, ensuring the smooth flow of the “aorta” and “microcirculation” of logistics.

In the distribution center of Shanghai Hongming Supply Chain Co., Ltd., tens of thousands of key components from more than 10 countries and regions such as the United States, Japan, South Korea, and the Netherlands are classified and placed, ranging from heavy equipment to small coil gaskets. It is called the “granary” of the integrated circuit industry.

“We communicated with various photoresist suppliers, adopted the ‘group purchase’ and ‘charter plane’ model, and cooperated with airports, customs, and China Eastern Airlines logistics, and planned to deliver a batch of photoresist every month.” Shanghai Hongming Supply Chain Co., Ltd. allocated Bai Li, senior manager of the center, said, “Under the guarantee of the whole process, products can be transferred from this component ‘granary’ to all parts of the country on the same day.”

A corner of Shanghai Hongming Supply Chain Distribution Center photographed on May 20. Imported integrated circuit parts and components from more than a dozen countries and regions such as the United States and Japan are rotated here.Photo by Xinhua News Agency reporter Zhou Lin

With the gradual resumption of work and production by enterprises, the throughput of the airport has also achieved a steady recovery. According to data from Shanghai Airport Group, since May, Shanghai Pudong Airport’s cargo and mail throughput has continued to rebound, with an average of 118 cargo flights per day and an average daily cargo volume of more than 5,300 tons, an increase of 37% and 64% respectively over the same period in April.

The construction of Shanghai International Shipping Center has been built through the collection and distribution system for more than 10 years, and has formed a comprehensive logistics advantage. In the epidemic, multimodal transportation can effectively reduce congestion and ensure smooth operation, which is the “ballast stone” to ensure the normal operation of enterprises.

“More than 20,000 employees have been operating in the port area for nearly two months, and they are relentless to guard their positions day and night to ensure uninterrupted loading and unloading production.” Zhou Yong, assistant to the general manager of the production business department of SIPG, said that at the end of March, at the The night before the Shanghai port area implemented the closure and control operation management measures, more than 20,000 employees received an emergency notification and rushed to the port area from all directions to concentrate on office work to ensure the 24-hour orderly operation of the Shanghai port.

In response to the pressure of road transportation being blocked, COSCO SHIPPING and China Railway Shanghai Bureau took active actions to increase the proportion of water-water transfer and sea-rail combined transportation to ensure the smooth flow of the “aorta” of the logistics chain. Among them, railway transportation not only relieves the pressure of road transportation, but also realizes regional linkage. From May 1st to 21st, the average daily unloading of the Yangtze River Delta Railway reached 17,507 vehicles, a year-on-year increase of 19.2%.

On May 26, my country’s first river-ocean intermodal LNG ship “Legend Sun” built by Hudong Zhonghua Shipbuilding, a subsidiary of China State Shipbuilding Corporation, was delivered in Shanghai.

Accompanied by the sound of the whistle, the economic giant, which has always been fighting against the market storms, smashed the waves and opened a new voyage… (Reporters Qi Zhongxi, Yao Yujie, Jia Yuankun, Zhou Rui, Zhou Lin, Gong Wen, He Xinrong)

[

责编:杨煜 ]