Ye Xinran, reporter from Economic Observer Network On the evening of July 18, Xia Qianliang, general manager of Zhang Xiaoquan Co., Ltd., responded that the topic of his evaluation of “Chinese knife skills are not as good as Michelin chefs” was an interview video a long time ago, and the current video was not based on the situation and context at that time. description, which leads to a great misunderstanding. Xia Qianliang also said that the company will launch the “Broken Knife Calling Order” project. If there has been a broken knife accident in the past five years, including the Zhang Xiaoquan brand and designated peer brands, new knives can be exchanged for similar models and similar values. .

On July 19, the reporter called Zhang Xiaoquan, and a person from the company’s securities department said that the company will announce the details of which other brands will be included in the near future. Because there are many operational processes involved, it will be a little later and will be released through the official platform later.

Regarding the “Michelin” remarks mentioned by the general manager of the company in the online video, the reporter asked what kind of situation he made it in. The person from the securities department said that because he had not seen the complete video personally, there was no way to accurately describe it, ” However, we also felt that the intercepted section was inappropriate, so we apologized yesterday.”

Non-core technologies are used in foundry products

Zhang Xiaoquan, who has a long history of nearly 400 years, encountered a hurdle in 2022. From “can’t shoot garlic” to “Michelin restaurants don’t cut it like this”, successive topics brought this century-old brand to the forefront.

Looking at the production capacity of Zhang Xiaoquan’s products, it can be found that more than 70% of the knives and scissors of this century-old brand are actually produced by OEM.

According to the prospectus, in 2020, the company’s overall output of cutting tools will be 6.598 million, of which 1.463 million are self-owned, 5.135 million are OEM (OEM), and OEM production accounts for 78%; the company’s total output of scissors It is 26.8126 million pieces, of which 7.0964 million pieces are self-produced, 19.7162 million pieces are OEM production, and OEM production accounts for 74%; 97% of other household items are from OEM.

According to the prospectus, in general, in 2020, 77% of the company’s products will come from foundries.

The company stated in the prospectus that in terms of scissors, the company’s self-produced products mainly focus on mid-to-high-end products, and OEM products mainly focus on mid-to-low-end products; for the combination of knives and sets of knives and scissors, the company’s self-produced products and OEM products have basically the same product positioning; other For daily household items, the company produces less products, and is basically produced by OEM manufacturers.

Zhang Xiaoquan explained that the company is in a stage of rapid development, and there is a situation where the production capacity cannot meet the continuous growth of sales. In order to solve the above problems, the company meets the growing demand of the downstream market through outsourcing processing, increases market share and enhances market visibility.

But on the other hand, as seen from the prospectus, the utilization rate of the company’s own production capacity is declining year by year, from 101.62% in 2018 to 86.76% in 2020.

The above data is the situation in 2020. Since the proportion of the company’s own production and OEM production in 2021 is not disclosed in the annual report, the reporter asked the above-mentioned person in the securities department for confirmation, and he said that it is not clear. As of press time, no more specific information has been received. Reply.

Zhang Xiaoquan continued to make efforts in marketing. The company’s annual report in 2021 shows that its sales expenses will reach 117 million yuan, a year-on-year increase of 41.08%, and its research and development expenses will be 22.8777 million yuan, a year-on-year increase of 14.02%. In the first quarter of 2022, the company’s sales expenses were 34.3168 million yuan, a year-on-year increase of 74.37%. The company said that it was mainly due to the increase in online platform traffic fees; the company increased brand promotion efforts on e-commerce platforms such as Douyin, and the corresponding investment fees and brand promotion. In the first quarter, the company’s research and development expenses were 5,239,200 yuan, compared with 4,384,000 yuan in the same period last year.

During the IPO stage, the Issuance Examination Committee focused on Zhang Xiaoquan’s OEM issues. Zhang Xiaoquan said in his reply to the inquiry that in order to ensure that the products produced by OEM suppliers have certain guarantees, the company will hand over some non-critical core technologies to OEM suppliers for production. use.

Zhang Xiaoquan said that the company’s main core technologies are used to produce self-made products, and the company has not handed over these technologies to OEM suppliers for production and use.

It is worth noting that the links involving scissors life detection technology are all produced by OEM manufacturers, and the Issuance Examination Committee also highlighted this aspect in the third round of inquiries.

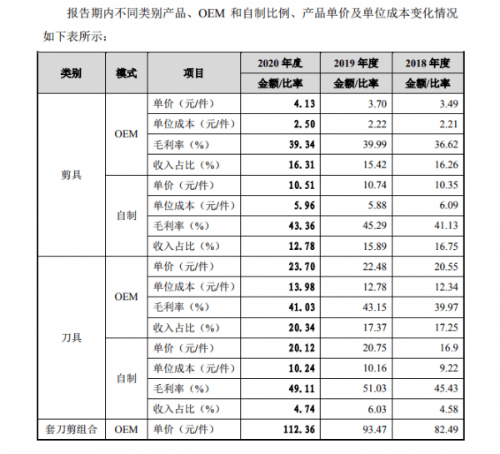

In Zhang Xiaoquan’s reply to the inquiry, it can be seen that in 2020, the unit cost of scissors from OEM is 2.50 yuan/piece, and the unit price of the product is 4.13 yuan/piece; the unit cost of self-made scissors is 5.96 yuan/piece, The unit price is 10.51 yuan/piece. The unit cost of the OEM tool is 13.98 yuan/piece, and the unit price is 23.70 yuan/piece; the unit cost of the self-made tool is 10.24 yuan/piece, and the unit price is 20.12 yuan/piece.

(The picture comes from Zhang Xiaoquan’s reply to the second round of inquiries)

The foundry said that using a knife to beat garlic deviates from the main purpose

So what kind of knife is suitable for slicing garlic? Zhang Xiaoquan’s securities department said, “In fact, there are tools such as garlic presses in the company’s products.”

The reporter asked Zhang Xiaoquan’s foundry, Yangjiang Chule Industrial Co., Ltd., in the form of business consultation. This is a large supplier who has cooperated with Zhang Xiaoquan for many years. In 2020, Zhang Xiaoquan purchased OEM semi-finished products from him, the amount of knives and knife sets It is 26.5965 million yuan, accounting for 11.80% of its current OEM purchases. A business person of the company said, “The phenomenon of knife breaking will happen no matter what brand or material it is, it is a matter of chance. Will the garlic be broken with a knife? It’s like turning a screw with scissors will not damage it, it’s a bit biased towards its main purpose.”

He said that the toughness of the knife will be affected by many uncontrollable factors. For example, the heat treatment furnace has not been heated to the specified temperature, and the workers are eager to put the knife on it early.

According to a statement released by Zhang Xiaoquan earlier, the product involved is a “dragon-sparrow cutting dual-purpose knife”, and the blade is made of 50Cr15MoV stainless steel. The above-mentioned business people said that 50Cr is characterized by a higher degree of sharpness and durability. If it is used for slicing garlic, a machete is more suitable than a kitchen knife, because the machete is a little thicker, and the thickness of the dual-purpose knife is between the two.

Xia Qianliang, general manager of Zhang Xiaoquan Co., Ltd., said in an interview with the media whether the proliferation of “pseudo-national fashion brands” means that the threshold for brand innovation has become lower, “For example, as a brand owner, if I am a brand owner, if I have an understanding of Chinese culture The understanding of Chinese elements is still superficial. The thing I rubbed on is actually on the surface, but not on the inside. If you want to be called a Chinese brand, please take out that thing, if you can make it When consumers around the world see it, they know it’s from China, so congratulations on your success.”

In the previous statement, Zhang Xiaoquan said that it will continue to develop and truly “know the Chinese kitchen better”.Return to Sohu, see more

Editor:

Disclaimer: The opinions of this article only represent the author himself, Sohu is an information publishing platform, and Sohu only provides information storage space services.