Current technology firmly in Asian hands

A good 30 employees develop and produce here. Sales have climbed to more than six million euros within just a few years. However, mass production does not take place in Nordhausen; niche applications are more at home there – and development services on behalf of third parties such as BMW. New materials, for example, can be tried out here using the standard format and manufactured under industrial conditions.

“In the area of lithium-ion cell technology and also the price level that is currently coming from China, we will remain dependent on that for a long time. Nobody can keep up with this quality and at these costs. It will be many years before we can catch up take time,” says Deutmeyer.

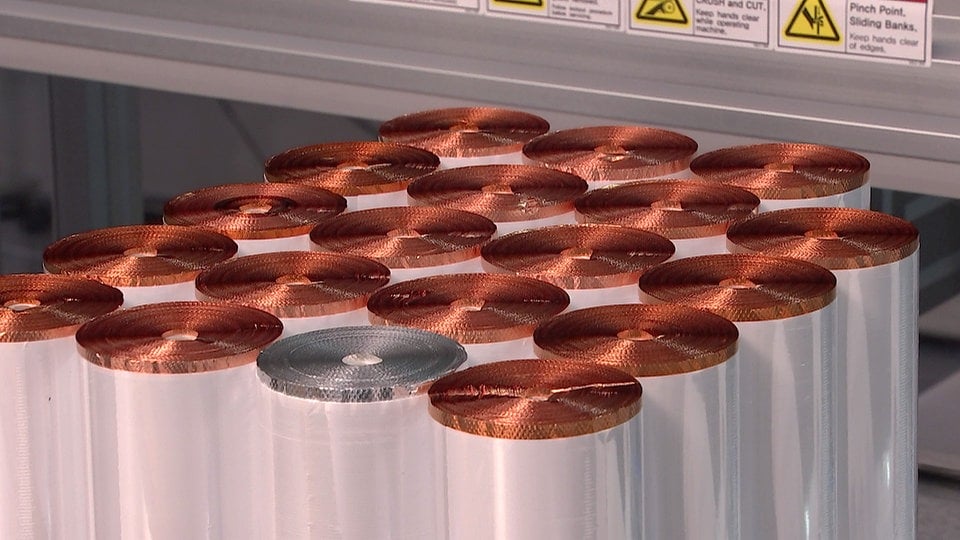

It’s about being more involved in the next battery generations. The manufacturer CATL, which operates a factory at Erfurter Kreuz, comes from China. Just like a large part of the machines and preliminary products that are assembled in Thuringia and then delivered to car manufacturers.

“In terms of value, the battery has the same value as an internal combustion engine,” says Rico Chmelik. He is managing director of the local Automotive Thuringia supplier association. “There is a high added value, the battery is valuable.” According to Automotive Thuringia, around 5,000 people are already working directly in the development and production of batteries in Thuringia.

Battery modules are manufactured at CATL and there will be 2,000 employees here. The battery management system production at Marquardt will be set up right next door and will have up to 800 employees. But with the cells there is a risk that the old dependence on Russian oil and gas will be exchanged for a new dependence, especially on China. So far, European companies have hardly played a role in cell production.

Prices for batteries are falling

It is therefore worth exploring whether one could try to create more value in Thuringia. The association had this investigated by the Chemnitz University of Technology. Researchers at the Chemnitz Automotive Institute (CATI) have determined that the need for batteries is increasing – simply because of more and more electric cars.

Nevertheless, the researchers expect the prices for the batteries to fall. By 15 percent by next year, by 40 percent by 2030. Provided the raw materials do not become more expensive, according to the CATI study.

The scientists consider the political goal of having around 60 percent of new cars to be electric by 2030 to be too ambitious, but the Chemnitz residents predict a 50 percent share. There is enough manufacturing capacity for this, but they are mostly in Asian hands. And in the case of China, for example, there is definitely concern that there will be too much dependence.

The Corona lockdown of the Chinese ports showed that supply chains are sensitive. If China stops delivering, car factories here could come to a standstill if there are no batteries.