In a technology company in Tianjin, workers are inspecting the wind turbine reducer box.Xinhua News Agency reporter Sun Fanyue/Photography

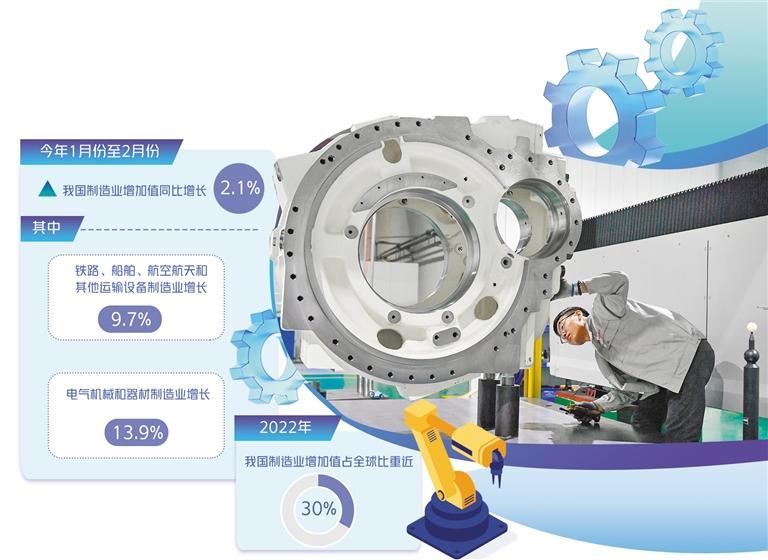

According to data recently released by the Ministry of Industry and Information Technology, in 2022, the added value of my country’s manufacturing industry will account for nearly 30% of the world‘s total, and the scale of the manufacturing industry has ranked first in the world for 13 consecutive years. “The bigger one is bigger”, how does China’s manufacturing industry form such a scale advantage? How to find new strengths? With these questions, the reporter interviewed relevant experts.

“Double-wheel” driving quantity and quality

According to the latest data from the National Bureau of Statistics, from January to February this year, the added value of my country’s manufacturing industry increased by 2.1% year-on-year. Among them, the manufacturing of chemical raw materials and chemical products increased by 7.8%, the manufacturing of railways, ships, aerospace and other transportation equipment increased by 9.7%, and the manufacturing of electrical machinery and equipment increased by 13.9%.

The accelerated scale expansion and quality improvement of some subdivided industries have supported the scale of my country’s manufacturing industry to rank first in the world for 13 consecutive years. According to statistics, the added value of traditional industries such as chemical products, non-metallic mineral products, and metal products accounted for 28.8% of the total manufacturing industry from 23.5% in 2010; communications equipment, computers and other electronic industries representing emerging industries The proportion of the added value of equipment increased from 6.5% in 2010 to 7.6% in 2021, and the performance of general and special equipment manufacturing, electrical machinery and equipment manufacturing, and transportation equipment manufacturing was relatively stable.

“The improvement of the competitiveness of traditional industries and the accelerated rise of emerging industries together support the continuous expansion of my country’s manufacturing industry, and has always maintained the status of the world‘s largest manufacturing power.” Guan Bing, director of the Industrial Economics Research Institute of CCID Research Institute, said.

At the Boao Forum for Asia Annual Conference 2023 being held, there is a lot of discussion on whether China is still the “world factory”. Over the years, the productivity level of China’s manufacturing industry has been continuously improved. Enterprises build factories in China with low production costs and high production efficiency, attracting various types of capital to invest and build factories, forming the scale advantages of China’s manufacturing industry in terms of production capacity and output.

Zhao Gang, president of Saizhi Industrial Research Institute, believes that my country has undergone two major transformations to become a “world factory”. The first time is to rely on huge market advantages, labor force advantages, raw materials, land and energy advantages, and preferential policy advantages of reform and opening up. , has attracted global manufacturing companies to invest and build factories, and realized the gradual transfer of the low-end manufacturing links of the global manufacturing industry chain to my country. Manufacturing companies are mainly engaged in product manufacturing for the Chinese market and “three to one compensation” for the global market And other product manufacturing, enterprises pay more attention to the cost advantage of Chinese factories.

The second time is to rely on the advantages of industrial chain clusters, logistics supply chains, production technology, industrial workers, industrial supporting environment and policy advantages to realize the overall layout of the global manufacturing industry chain in my country. The Chinese market is also facing the global market. Our factories have the dual advantages of high production efficiency and low production costs.

At present, from a regional perspective, all regions are actively developing manufacturing industries. The eastern region has accelerated its transformation and upgrading, taking the lead in cultivating a number of emerging industries. Guangdong, Jiangsu, Shandong, Zhejiang and other dominant provinces have continued to consolidate their status and played the role of “leader”. The central region and some western regions have risen rapidly, Sichuan, Anhui, Jiangxi The proportion of the national manufacturing industry continues to rise, and it has become a “rising star” that continues industrial growth. “From a regional perspective, several economic growth poles such as the Yangtze River Delta, Pearl River Delta, and Chengdu-Chongqing are taking shape, becoming important growth poles to stimulate the development of the manufacturing industry.” Guan Bing said.

A dialectical look at “big” and “strong”

In 2022, the added value of my country’s manufacturing industry will account for 27.7% of GDP. Among the world‘s 500 major industrial products, the output of more than 40% of our products ranks first in the world. 65 manufacturing companies have been shortlisted for the list of the world‘s top 500 companies in 2022, and more than 70,000 specialized, special and new small and medium-sized enterprises have been cultivated. According to the classification of national economic statistics, my country’s manufacturing industry has 31 major categories, 179 middle categories and 609 subcategories. It is the manufacturing industry with the most complete industrial categories and the most complete industrial system in the world.

It is often said in the industry that China’s manufacturing industry is large but not strong, so many people think that the advantages of scale are not of much use. In this regard, Xu Zhaoyuan, deputy director of the Industry Department of the Development Research Center of the State Council, said that technological progress in the manufacturing industry has a very important “learning by doing” effect. The larger the production scale of many products, the easier it is to improve technology in production and improve product quality. ,Increase productivity. The scale of my country’s manufacturing industry continues to increase, and the advantages of production efficiency in the core competitiveness of the manufacturing industry have an important foundation. This includes industrial supporting advantages, industrial scale advantages, etc., which can significantly reduce costs.

The “big” of my country’s manufacturing industry provides a solid foundation for “strong”. Zhao Gang believes that “big” has enabled my country’s manufacturing industry to form an advantage in economies of scale. Many product orders can only be produced in my country with large-scale, high-efficiency, high-quality, and low-cost production. For example, the same electromechanical or equipment product is manufactured in China. , the raw materials are sufficient, the abrasive tools can be matched nearby, and the whole machine can be mass-produced.

“Big” can provide more funds, talents and application scenarios for the technological progress of the manufacturing industry, promote my country’s manufacturing industry to accelerate investment in technology research and development, improve product research and development design, high-end production equipment, advanced process design, advanced basic materials, and achieve high-end manufacturing Smart, intelligent and green transformation.

“Big” can also provide more strong support for the rise of Chinese brands. In recent years, Made in China is becoming synonymous with high quality, high efficiency, and high cost performance, laying the foundation for Chinese local brands to grow bigger and stronger and form a global influence.

my country’s manufacturing industry has a large scale and a complete range of categories, which to a certain extent ensures that the manufacturing industry has strong resilience, large maneuvering space, and strong anti-risk capabilities. This has been more prominent in responding to sudden epidemics and resuming work and production. In addition, “new fields and new tracks are to a large extent the extension of the chain extension and supplementary chain on the basis of the existing manufacturing industry, or new applications and new formats derived from the existing industry through digital empowerment and other means. The new model and sound manufacturing system provide more space for the selection and cultivation of my country’s future industries.” Guan Bing said.

Experts believe that my country’s manufacturing industry is “big but not strong” mainly referring to the large production capacity and output of my country’s manufacturing industry, but there are still many problems in product R&D and design, high-end production equipment, advanced process design, advanced basic materials, and high-end brands. Short board, compared with the United States, Germany, etc., my country is not yet a manufacturing powerhouse. The two key factors for my country’s manufacturing industry from growing bigger to stronger, from quantitative change to qualitative change, are technological progress and corporate brand building, making Chinese manufacturing companies more competitive at both ends of the “smiling curve”.

Create new competitive advantages

Thanks to the application of the Inspur Haiyue enterprise digital platform, Shandong Fangyuan Group has reduced its labor force by about 40%, reduced production costs by more than 30%, increased production efficiency by 60%, and significantly improved product quality consistency. Home benchmark bridge and tunnel equipment manufacturing intelligent factory.

At present, the advantages of high production efficiency in my country’s manufacturing industry are relatively prominent, and it still has the advantages of industrial chain clusters, logistics supply chains, production technology, high-quality industrial workers, domestic market, industrial supporting environment, and industrial policies, which further positively enhances economies of scale advantage, but the comparative advantage in terms of production cost is gradually weakening. The new advantages of my country’s manufacturing rely on high-end, intelligent and green, and improve the comparative advantages in production efficiency, production cost and green manufacturing, and attract global manufacturing companies to continue to expand investment and build factories.

Zhao Gang believes that in terms of high-end, we should give full play to my country’s advantages in brand, technology research and development, and complete machine manufacturing in the fields of clean energy, nuclear energy, electric vehicles, new transportation, ships, equipment manufacturing, electronic home appliances, mobile communications, etc. Downstream enterprises form industrial chain clusters in my country. In terms of intelligence, we should give full play to my country’s first-mover advantages in the field of digital economy, accelerate the digital transformation of the manufacturing industry, build smart factories, “lighthouse factories”, develop the industrial Internet and consumer Internet, and use digital technology to enhance the large-scale customization of my country’s manufacturing enterprises. , flexible production, and networked collaboration capabilities, further improving production efficiency and supply chain collaboration efficiency, reducing production costs, and forming a more competitive efficiency and cost advantage in China’s manufacturing industry.

Traditional industries account for 80% of the manufacturing industry, which is the key to building a manufacturing power. But at present, all places pay more attention to emerging industries. In this regard, Guan Bing said that emerging industries as a whole are still in the development stage, and it is still difficult to fill the gaps in traditional industries in the short term. The development of the manufacturing industry must walk on “two legs”. Intelligent and green development, fostering advanced manufacturing industry clusters, consolidating and upgrading traditional advantageous industries; on the other hand, combining the advantages of local resource endowment, cultivating a number of emerging industries and future industries, creating a new engine leading future growth, and building a modern industrial system , to promote the steady and long-term development of my country’s economy.

In order to consolidate existing advantages and find new ones, the primary task of my country’s manufacturing industry is high-quality development. The key path is technological progress, improving total factor productivity, and consolidating the comparative advantages of my country’s manufacturing industry in global competition. “The first is ‘keeping the right’. We must continue to improve the competitiveness of my country’s industrial chain clusters, supply chain efficiency, industrial workers’ skills and brand influence, and maintain the combined advantages of high production efficiency and low production costs in my country’s manufacturing industry. The second is ‘innovation’, We must focus on creating an innovation chain, improving the level of high-end, intelligent, and green manufacturing, building a world-renowned brand, and forming a new competitive advantage in the manufacturing industry.” Zhao Gang said. (Huang Xin)

[

责编:陶媛 ]