It’s a bio-inspired, crafted hand-wrist brace studying the properties of the silkworm cocoon, of which it reproduces the reticular structure capable of guaranteeing flexibility, resistance and breathability at the same time. The aid, customizable on the individual patient with amyotrophic lateral sclerosis and other neuromuscular pathologies to help him against the atrophy of the hand-wrist muscle that heavily hinders daily life, was created by a team of researchers from the «3D printing Lab» in Milan, one of the ten laboratories of Nemolab. «The silkworm cocoon has inspired many solutions in various fields, not only in biomedicine. We started from the characteristics of the geometric structures produced by the bug» he explains the young bioengineering researcher Silvia Badini, first author of the study appeared in the magazine Biomedicines

Nature is a reservoir of ideas from which human beings have always drawn inspiration. While not the absolute best engineering solutions, those resulting from evolution are still the best adaptive response, the result of a very long evolutionary selection. The work of human ingenuity is to simplify, adapt, perfect what already exists on the basis of one’s own objectives. From movement and flying to air purification, there are countless examples of so-called bio-inspired solutions, from materials science to robotics and biomedicine.

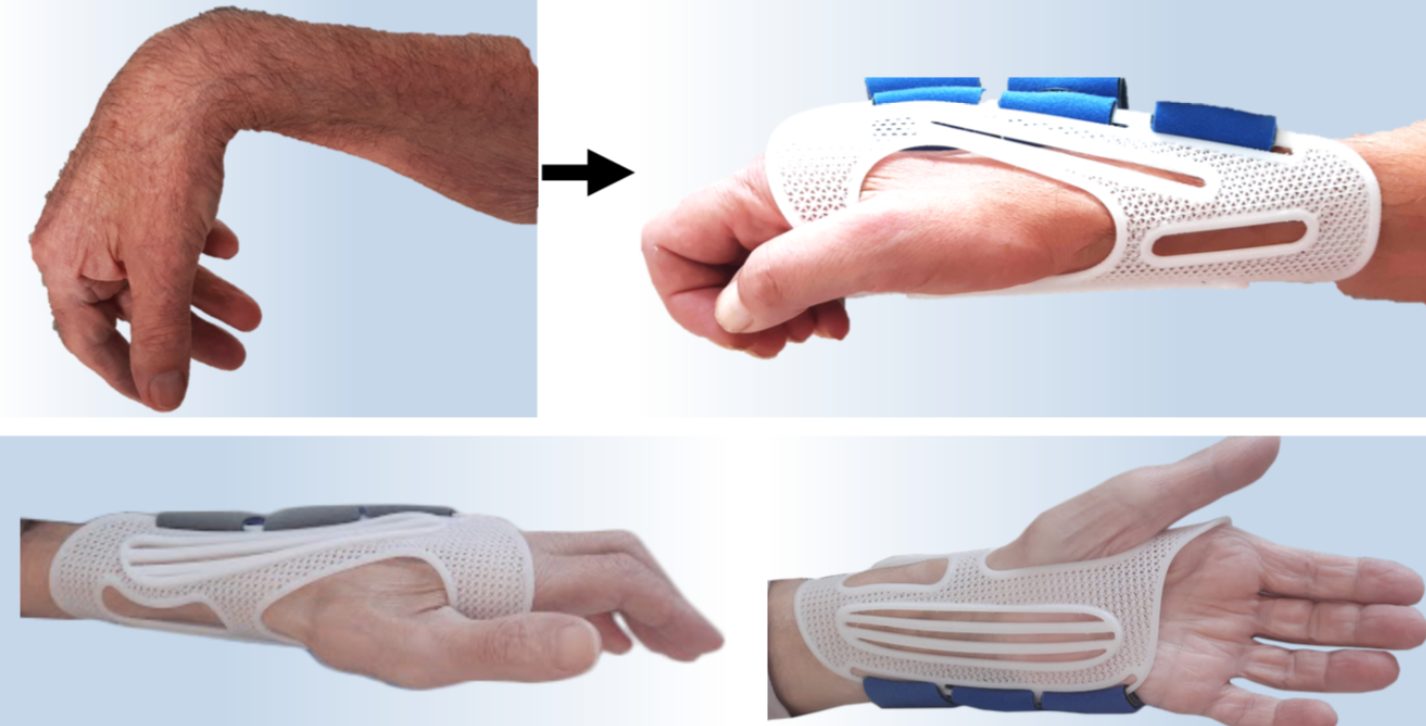

From the reticular geometry of the silkworm, through computational simulations, to the bio-inspired structure that will then be 3D printed (photo: Nemolab)

«We have computationally studied the mechanical characteristics of the structure of the net of the bug, identifying not only resistance and flexibility but also an ability to adhere to three-dimensional surfaces that we call form-fitting. Therefore, we chose a synthetic polymer called poly-ε-caprolactone, already widely used in medical technologies because it is biocompatible, bioresorbable and biodegradable» explains Badini. A real biomaterial, a term that defines all those molecules, including synthetic ones, used in devices that can be implanted in our body or in any case intended to interface or integrate with it. Finally, thanks to 3D printing, the group has reached the final aid, personalized on the single patient.

«The triad of bio-inspired structure, biomaterial and three-dimensional printing has led us to an aid designed on the individualwhich takes a couple of hours to be ready unlike the two months used by traditional manufacturing, and which can be reprinted as the disease progresses and as the patient’s needs change, recycling the production material» he explains to us Raffaele Pugliese, coordinator of the Nemolab research area and head of the study. The technology is ready, the orthosis is an industrial prototype and the cost of such a brace is lower than those on the market and further reductions in production costs are conceivable by reasoning in terms of scale and reuse of materials.

Silvia Badini and Raffaele Pugliese (photo: Nemolab)

People with ALS have been involved from the beginning, in the identification of the needs to be satisfied, which the scientists have translated into functional and structural aspects of the orthosis, and subsequently, in the evaluation of the product, judged to be breathable, thin, aesthetically pleasing, lightweight, and easy to use. The researchers conclude: “At the heart of a paradigm shift in research design and prioritization, the role of the patient is fundamental in dialogue with clinicians and researchers and NeMO centers have long since adopted this approach.”

«Personalisation also means being able to respond to the new needs linked to the progressive weakening of the hand muscles in ALS and makes this technology that can also be potentially extended to other areas of the body, such as the neck and head, in other neurodegenerative diseases and for spinal injuries» comment the researchers «We hope it can be included in the process of taking care of the patient». Now the team is working to «make this orthosis more and more performing, from a circular economy perspective, as established by the sustainable development goals, in line with the ongoing change in tissue engineering by aiming for increasingly sustainable and smart materials, capable of releasing pharmacological molecules for various purposes in a controlled way”.

Main photo: Nemolab